ABOUT RELOWELD TECHNOLOGY CO.,LTD

Established in 1998, Shenzhen ReloWeld Technology Co., Ltd with several domestic brand names ReloWeld, Weldtec, RilanWeld has grown to become one of the largest and most innovative manufacturers of welding machines, air plasma cutting machines in various industrial applications. With an advanced quality control system, R&D capability, and and orderly production management system, ReloWeld has earned a reputation for excellence in the welding equipment industry at home and abroad.

Shenzhen ReloWeld Technology Co.Ltd, as a leading welding machine manufacturer in China, offers a wide range of products, including MMA welders, ARC welders, MMA welders, TIG AC/DC welders, TIG welding machines, DIY MIG/MAG welders, professional MIG/MAG pulse welding machine, Air plasma cutter, Oil-free Air Compressor, Belt-driven air compressor, direct-driven air compressor, etc. We are committed to our customers, and are always willing to go the extra mile. We are easy to work with and believe in getting it right every time. An email, call, or request never goes unanswered and everyone at ReloWeld will do what it takes to accommodate the needs of our customers.

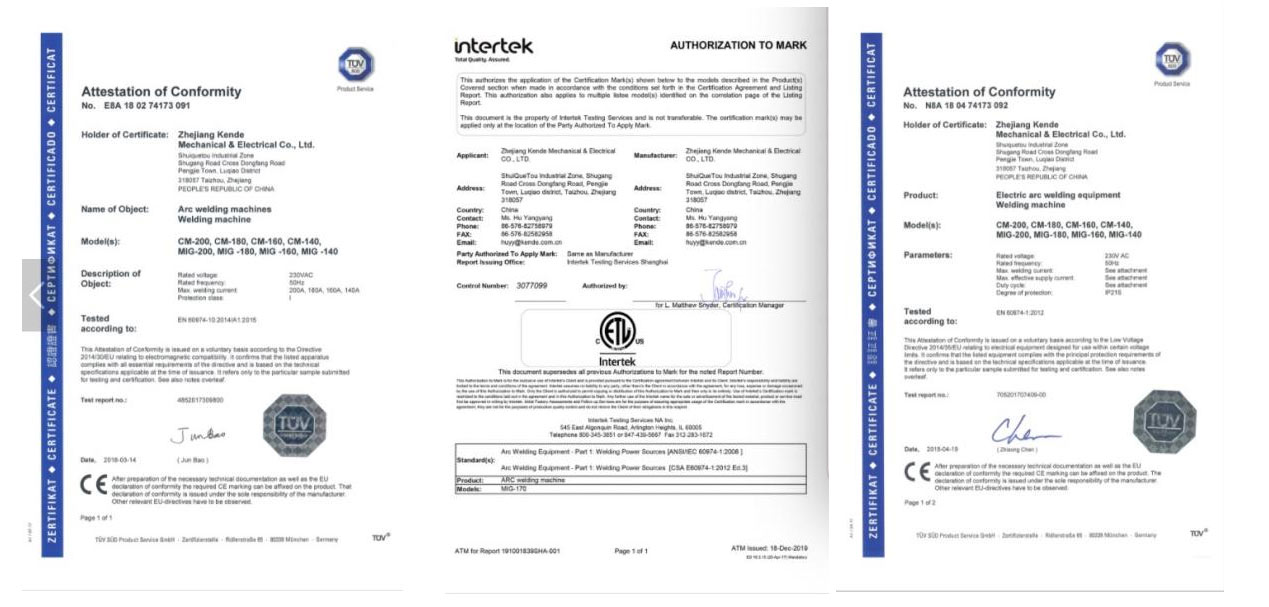

Many of our products have obtained BSCI, CCC, CE, EMC, GS, ROHS, CSA, and ETL approvals, all products are produced and tested strictly per IEC60974-1, EN60974-1, EN60974-6 standards. While other companies have been in the welding machine industry longer than ReloWeld, no other company has surpassed the quality, service, and innovation provided by ReloWeld in recent times. With quality products, constant innovation, and excellent customer support, ReloWeld Corporation is unsurpassed in its pioneering efforts to provide better welding supplies and services throughout the world.

Contact us today with any questions you may have!

Vision&Mission

To create an exceptional welding and metalworking experience.We value people. Taking care of customers drives us. We develop products that are innovative and reliable.

History

2020

ReloWeld introduces an automatic Robot processing plant, and becomes the intelligence of the manufacturing leader in the industry.

2017

Setting up branches in Zhongshan and Foshan cities for supporting warehouse and shipment.

2013

ReloWeld expands into larger with more than 800 workers, and continues to care for all dealers in the world to whom they owe their success today.

2010

Pass the assessment of TUV NORD and achieve the ISO9001:2000 Quality Management System certification.

2007

ReloWeld became a member of the China Electric Welding Machine Standardization Technical Committee.

Built a number of industry-leading lead-free environment-friendly automated production lines (in line with EU ROHS standards).

2003

Authorized the EU CE marking and the license for selling products in the European market.

1998

Establishing brands ReloWeld & MegatecWeld in Shenzhen China by a group of welding technicians

R&D Capability

Our position is strengthened by continued R&D investment of no less than 8%of our revenue annually to upgrade the quality and efficiency of our existing products, in addition, we have deployed resources seeking a technological breakthrough in the high-end market segment.

As a major player in the industry, we are proud to have won market recognition for our leading position in R&D capability, especially in the field of inverter welding technology.

Honors & Qualifications

KNOW-HOW

Can you think of many objects that aren’t made with welded parts or welded themselves? It’s a hard task. We know welding is an integral part of the manufacturing process, but with so many different methods, it can be hard to understand the difference or determine which method is best. Most industrial companies stay on top of the advancements and changes in welding styles and techniques, but some don’t know where to start. Whether you’re unfamiliar or just in need of a refresher, read on for the differences between the most common welding methods used in manufacturing.

Welding

The concept of welding dates back to the medieval period with the heat and hammer process known as “forge welding.” Fast forward to the last 100 years and we can see the development of almost all of the modern welding innovations we have today. We’re now faced with a variety of welding methods – each with their own pros and cons. The two main welding methods related to our industry are MIG and TIG, but we will also cover another major method, Stick welding. The chosen method should depend on the metal, environment, application, speed and more.

What is MIG Welding?

Also known as Gas Metal Arc Welding (GMAW), MIG welding is the most common type of welding used by custom automation and manufacturing professionals.

Filler wire and shielding gas flow through the welding gun during MIG welding

Metals:

- Stainless Steel

- Mild Steel

- Aluminum Alloy

Chosen for:

- Speed

- Flexibility

- Minimal Clean-up

MIG welders utilize a wire welding electrode that is automatically spool fed at a constant speed. The electrical current between the wire and metal surface creates an arc that melts the wire and aids in the creation of a high-strength weld with little cleaning. An inert shielding gas flows through the welding gun along with the electrode and protects the weld from contamination. MIG welding can be used on stainless steel, mild steel, and aluminum as thin as 26-gauge and also on much thicker pieces as well. It’s probably the easiest method to learn and results in good looking, strong welds. Minimal clean-up is required, meaning little to no grinding or sanding.

Flux Core Arc Welding (FCAW) is a variation of MIG welding that is very similar, but does not require a shielding gas. Instead, it feeds a Flux-Cored wire to shield the arc as a simple approach that works well in heavily windy conditions or on dirty metals. It can be used on similar metals and in a variety of thicknesses. While this process is not widely used in manufacturing, it is mostly used in construction because of its speed and portability.

What is TIG Welding?

TIG welding, also known as Gas Tungsten Arc Welding (GTAW), is another arc based welding process that uses a non-consumable tungsten electrode to create the weld. Unlike MIG, filler wire is applied by hand.

Notice the handheld filler wire used with TIG welding

Metals:

- Stainless Steel

- Mild Steel

- Aluminum alloys

- Titanium*

- Chromoly*

- Copper*

- Brass*

- And more

* Indicates metals used exclusively with this method.

Chosen for:

- Highest Quality

- Best Looking Finish

- No Clean-Up

- Widest Variety of Metal types and sizes

- Thinner Metals

As the long name implies, this method also uses a shielding gas (often argon) and filler metal to protect the weld area from contamination. TIG welding is much harder to master and significantly slower than other methods, but it provides the greatest control capability which allows for stronger and higher-quality welds. As an added benefit, it’s also the cleanest method and often requires no excessive clean-up.

there are few things more visually appealing in our industry than quality stainless or aluminum TIG welds. Often referred to as “stacking” or “laying dimes”, skilled welders create welds that are as aesthetic as they are structural.

“Stacking dimes” with the use of TIG welding on stainless steel

What is Stick Welding?

Also known as Arc or Shielded Metal Arc Welding (SMAW), Stick welding is the most basic form of welding, but not necessarily the easiest to grasp. It is easy to master and very common in both heavy construction and at home.

Stick welding uses an electrode “stick” rather than a gun

Metals:

- Stainless Steel

- Steel

- Cast Iron*

* Indicates metal used exclusively with this method.

Chosen for:

- Thicker Metals

- Outdoor / Windy Environments

- Forgiveness with Dirty or Rusty Metals

Stick welding requires no gas but uses a consumable electrode “stick” that flows electric current between it and the metal surface. In some applications, the most common 1/8th-inch diameter electrode can be consumed in just one minute. It is still considered the most economical method. You’ve likely seen this type used in heavy-duty applications on ships, tractors, and more. That is because stick welding is best suited for thicker metal, usually with thicknesses of 18 gauge or more. Unlike the other methods, stick welding produces a lot of slags– the excess splatter you’ve probably seen during the welding process – and requires significant clean-up. It is the least common method used in general manufacturing, but good for applications that don’t require a clean finish.

Welding Resources

Welding is a diverse and continuously evolving process. There are many more methods and variations not discussed here. Whether you want a turn key product or just metal fabrication, let us put our welding services to work for you.